Filter by price

Community poll

How did you find us?

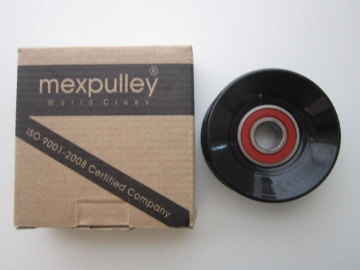

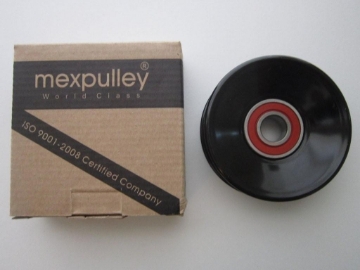

Idler Pulley - Tensioner Pulley

Idler Pulley - Tensioner Pulley

1. Durability and Longevity

- Wear Resistance: Metal idler pulleys are more resistant to wear and tear than plastic or composite ones, making them ideal for high-stress applications.

- Heat Resistance: Metals can withstand higher temperatures without deforming, which is crucial in automotive engines and industrial machinery.

- Corrosion Resistance: metal idler pulleys are resistant to rust and corrosion.

2. Strength and Load Capacity

- Metal pulleys can handle heavier loads and higher tension without deforming, making them suitable for heavy-duty applications.

- They perform well under continuous or high-speed operations where the load is substantial.

3. Precision and Stability

- Metal idler pulleys are machined to higher tolerances, offering better alignment and reduced vibration.

- This enhances the stability of the belt system and minimizes wear on the belt and other components.

4. Reduced Maintenance

- Due to their strength and resistance to wear, metal pulleys require less frequent replacement or maintenance, reducing downtime and costs in the long term.

5. Consistent Performance

- Metal pulleys maintain their shape and structural integrity over time, ensuring consistent belt tension and alignment, which improves the overall performance of the system.

6. Aesthetic and Customization

- Metal pulleys often have a professional appearance, our pulleys are anodized.

Common Applications:

- Automotive Systems: For engine belts, timing belts, and accessory drives.

- Industrial Machinery: Conveyor belts, HVAC systems, and manufacturing equipment.

- Outdoor and Harsh Environments: Where exposure to elements demands materials with superior durability.